Buy Ammo Online and Save with Our Low-Cost Ammo Deals

Buy Ammo Online and Save with Our Low-Cost Ammo Deals

Blog Article

Just How to Effectively Keep Your Ammo Depot for Durability

Preserving an ammunition depot for durability includes a complex technique that prioritizes safety and security, ecological control, and meticulous supply management. Managing environment problems and making sure correct packaging are critical to maintaining the stability of the ammunition.

Selecting the Right Storage Space Area

When selecting a storage place for your ammo depot, it's crucial to prioritize safety and security and accessibility. The selected site needs to be certified with regional regulations governing the storage space of hazardous products, ensuring that it satisfies all safety and security requirements. Select a location that is away from booming locations, lessening threat in the occasion of a crash.

Availability is an additional essential consideration. The depot must be located near vital supply courses to promote reliable transport of ammo, while also being protected sufficient to discourage unapproved gain access to. A well-planned accessibility path permits risk-free loading and unloading, decreasing the risk of injury or damage.

Furthermore, think about the physical characteristics of the website. Ground stability is important; prevent locations vulnerable to flooding or erosion, which could jeopardize the honesty of your storage space. All-natural obstacles can boost protection, so websites surrounded by fencings, wall surfaces, or all-natural landscapes need to be preferred.

Controlling Environmental Conditions

Efficient control of environmental conditions is essential for the conservation and reliability of kept ammunition. Aspects such as temperature level, air, and moisture high quality play a critical role in maintaining the honesty of ammo over time. Optimal storage space conditions typically call for a temperature variety of 60 to 75 degrees Fahrenheit and moisture degrees listed below 50%. Inconsistencies from these criteria can bring about deterioration, impacting performance and security.

To attain these conditions, make use of climate control systems such as air conditioning and dehumidifiers. Normal monitoring of temperature and moisture degrees with calibrated tools is advisable, permitting timely modifications to keep ideal problems. Additionally, making certain correct air flow can reduce the buildup of hazardous gases that might jeopardize the ammo.

In addition, it is vital to maintain the storage space location free and tidy from impurities, which can advertise corrosion and other types of destruction. Using bug control steps will certainly additionally aid stop infestations that can damage product packaging and stability. By consistently managing ecological problems, the long life and dependability of your ammunition depot can be substantially enhanced, making certain preparedness and effectiveness when required.

Normal Supply Administration

Routine inventory management is vital for guaranteeing the operational preparedness of an ammunition depot. This process includes systematically tracking the amount, condition, and place of all ammunition supply. Constant stock checks aid determine any type of inconsistencies between taped and real stock levels, which can show problems such as damage, theft, or misplacement.

Applying an organized stock monitoring system, such as an electronic tracking program, enhances precision and efficiency. Routinely set up audits-- performed quarterly or month-to-month-- enable complete assessments of supply and can discover possible risks or scarcities in advancement. It is essential to maintain comprehensive documents that consist of batch numbers, expiry days, and upkeep history to facilitate quick retrieval and compliance with safety and security regulations.

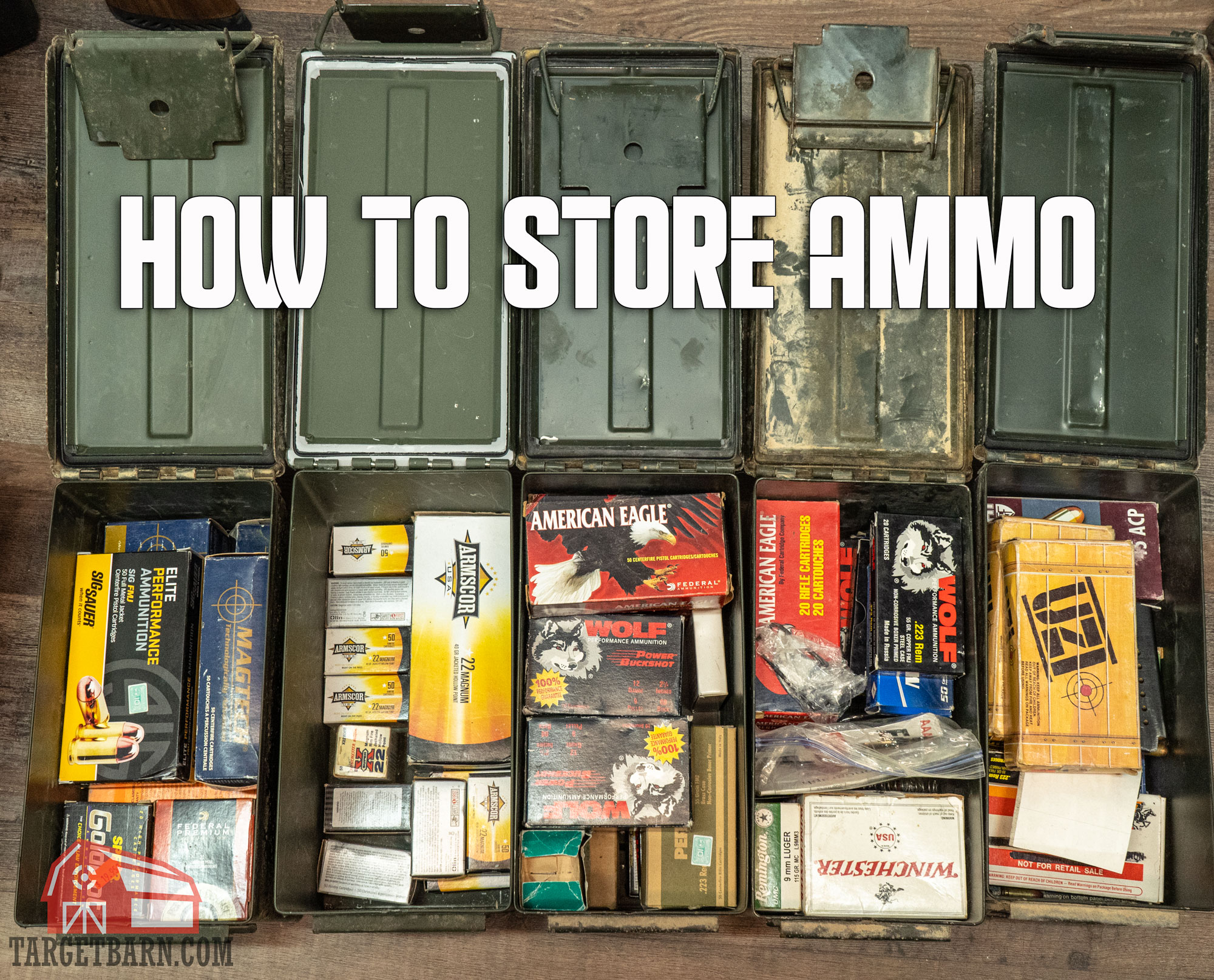

Making Certain Appropriate Packaging

Maintaining proper packaging for ammunition is a crucial facet that enhances effective stock management. The stability of ammunition product packaging plays a vital duty in making sure the security, integrity, and long life of the stored products. Using suitable product packaging products, such as moisture-resistant containers or sealed plastic bags, can considerably mitigate the threats of damage brought on by environmental factors.

Each bundle should be clearly classified with crucial info, including expiration, quality, and kind dates. This technique not just promotes reliable inventory monitoring yet likewise boosts security by protecting against the unexpected usage of incompatible or out-of-date ammunition. In addition, using stackable and durable containers can optimize storage area while reducing the risk of physical damage.

Proper packaging prolongs the life of ammunition and makes certain that it stays in optimal problem for use when needed. Sticking to these standards will help preserve operational preparedness and promote safety and security within the ammunition depot.

Carrying Out Regular Inspections

To conduct effective regular evaluations, establish a comprehensive list that covers crucial elements such as storage conditions, product packaging integrity, and stock accuracy. Pay specific focus to ecological check my site factors, including temperature and humidity, which can considerably impact the stability and safety and security of ammo. Examine the physical problem of storage space containers and make sure that they are cost-free from corrosion, leakages, or damage.

Furthermore, review the organization of the depot to help with simple gain access to and exact tracking of supply. This organization decreases the risk of crashes and makes certain effective access during operational demands. File all findings meticulously, keeping in mind any type of inconsistencies or issues that require instant focus. Establish a method for addressing recognized problems, including timelines for resolution and responsible employees.

Conclusion

To conclude, efficient maintenance of an ammunition depot necessitates cautious consideration of different factors. Selecting a proper storage space place, controlling environmental problems, performing routine stock monitoring, making sure proper product packaging, and executing routine examinations are all important parts. By sticking to these standards, the durability and safety and security of the ammo depot can be significantly boosted, eventually adding to the integrity and performance of operations while protecting workers and the surrounding environment.

Maintaining an ammunition depot for long life includes a diverse approach that focuses on safety and security, ecological control, and precise supply monitoring.When selecting a storage space area for your ammo depot, it's critical to prioritize security and availability. By consistently managing environmental problems, the long life and reliability of Resources your ammo depot can be substantially boosted, making certain preparedness and effectiveness when needed.

Normal stock monitoring is important for ensuring the operational readiness of an ammunition depot. Bulk Ammo Online. A society of watchfulness and stability in stock monitoring not only safeguards sources however also enhances the total dependability of the ammunition depot, inevitably supporting mission readiness and functional efficacy

Report this page